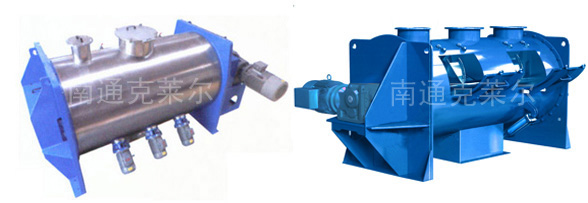

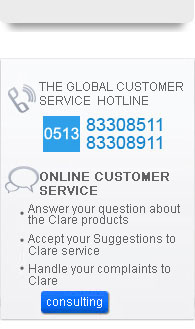

The coulter mixer consists of a cylindrical body, transmission, coulter and knife; When working, Coulter circularly motions, so the material is split into two directions by coulter surface forming material flow in two directions, intersecting with the material streaming by two flanks of the coulter to form convection.spilled by the knife blade to achieve uniform mixing in a relatively short period of time .

The machine has high mixing accuracy, with no segregation when mixed, especially for easy reunion materials, playing the role of depolymerization and beaten.Coulter mixer suitable for mixing powder, granular powder with powder and powder with a small amount of liquid,It’s widely used in industries of chemical, ceramics, fire pharmacy, carbide, friction materials, refractory materials, dry mortar and mining.The machine has large adaptability of mixture and can play the role of depolymerization and beaten for easy reunion materials,and can mix materials on the ratio from 1:1000 to 10,000 well.The machine can also be made in a variety of special forms of heating, cooling, positive pressure, vacuum, etc. according to the user's request.

|